Researchers succesfully grow GaN microLED arrays on a flexible graphene substrate

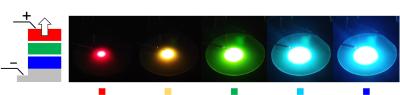

Researchers from Korea's Seoul National University and Sungkyunkwan University developed a method to grow GaN LED arrays on a flexible graphene layer. The so-called microdisks arrays exhibit excellent crystallinity with a uniform in-plane orientation and strong blue light emission.

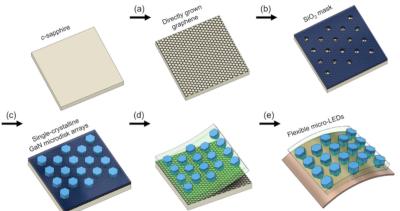

The researchers grew the GaN microdisks on a graphene layer (grown on a sapphire substrate) covered with a micro-patterned SiO2 mask using metal–organic vapor-phase epitaxy. The microdisks were then processed into micro-LEDs and then successfully transferred onto bendable substrates.