Coherent manufactures several key AR display components and is actively working to improve the technology.

This is a sponsored message by Coherent

Virtual reality (VR) and augmented reality (AR) have received a lot of media buzz over the past few years. They promise benefits for applications are as diverse as gaming, healthcare, training, engineering, architecture, interior design, travel, defense, and even product marketing. But today, VR/AR still hasn’t had a significant impact on most people’s lives.

Two main reasons for this are VR/AR headset quality and cost. Specifically, quality includes factors like image brightness, resolution, field-of-view, and electronic characteristics like speed and power consumption. Plus, practical considerations, including headset size, weight, and battery lifetime are also important. And cost means bringing down headset prices low enough to make them accessible to most consumers.

The AR Challenge

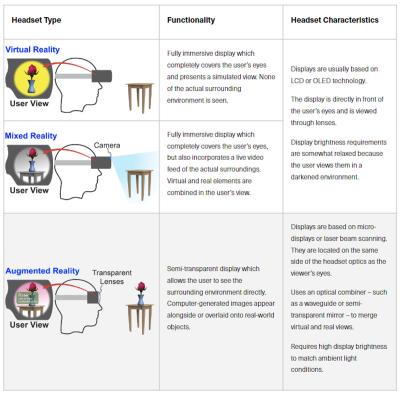

There are numerous technical hurdles to overcome in driving improvement in all these areas. And these challenges are generally bigger for AR than for VR headsets. To understand why, let’s first review what these terms specifically mean. The definitions are summarized in the table.

A key characteristic of VR and MR headsets is that the displays are viewed directly – that is, they sit right in front of the viewer’s eyes. This enables the use of relatively simple, conventional viewing optics similar to those used in instruments like microscopes, binoculars, and rangefinders. Although VR optical systems are much more compressed in terms of size.

In contrast, the displays in AR goggles are not in the field of view of the user, and therefore require sophisticated optics to redirect the light towards the user’s eye. The display output must be combined with the wearer’s direct view of the environment to make virtual objects appear to be out in the real world. The optics to accomplish this – usually beam splitters or waveguides – are much more complex and sophisticated than VR headset lenses.

Furthermore, it’s necessary that the computer-generated images appear in the right position, distance, and orientation in the real-world view. This requires the headset to continually track the user's head and body movements and also determine the size, position, and orientation of objects in the real-world environment. While most VR headsets also incorporate some head and body movement tracking, the requirements for this in AR are generally more demanding.

The Future of AR is clear

Coherent is already actively involved in developing photonics-based solutions for these issues for AR systems. We’re mainly focused on three functional elements of AR headsets – the display projector (or light engine), the optical combiner, and the optical sensors.

Display Engines

Most AR headsets use MicroLED or laser beam-scanning light engines. Coherent is well-established in delivering a key technology for MicroLED production. Specifically, Coherent tools perform Laser Lift-off (LLO) to separate MicroLED from the sapphire wafers they’re grown on. Sometimes LLO is followed by Laser-Induced Forward Transfer (LIFT), which can be performed with our UVtransfer (which performs LLO and pixel repair/trimming, as well).

Coherent also has extensive expertise in fabricating some of the miniaturized optical components used in display projectors. One of the most interesting of these is “meta-surface” micro-lens arrays for collimation.

A meta-surface lens utilizes nanostructures to alter the wavefront of incident light. The features are manufactured with high precision and can be aligned with tight tolerances over the MicroLED array, collimating the light from individual emitters. A meta-lens is flat and very thin, so it can be integrated seamlessly into a display engine package.

An added bonus is that meta-lenses can fabricated using lithographic or other wafer-scale technologies. This means they can be produced economically in high volumes. So, this technology is an ideal match for the requirements of AR goggles.

Coherent also provides other optical components for light engines. These include RGB combiners for Laser Beam Scanners (LBS) or thin-film polarizers for LCOS displays, and a wide range of optical coatings that can be applied on various types of glass or integrated into the optical stack of almost any optical element.

Optical Combiners

Collecting the display output and redirecting it so that it appears overlaid with the wearer’s direct view of their surroundings is probably the single biggest photonic challenge in AR headset set design. A number of highly innovative design concepts are currently being pursued by different groups to accomplish this. Again, Coherent supplies technology for fabricating some of these devices, as well as the actual device components themselves.

In many headsets the goggle lenses are waveguides. These channel light from the display (located in the frame) towards the user’s eye. The waveguides have input couplers near the display engine and output couplers in the center of the lenses. These output couplers are implemented either as surface relief gratings (SLG) or holographic optical elements (HOE).

HOEs are recorded in photopolymers using lasers. Specifically, this is accomplished using three laser sources – red, green, and blue. As with other forms of holography, the laser sources for this must be single frequency, have a long coherence length, operate with high stability, and preferably output high power (to minimize exposure time).

oherent Genesis and Verdi lasers have all of these characteristics, making them an ideal choice for recording HOEs.

Coherent can also fabricate several different beam combiner components, including the lens material itself. Some of the leading AR companies are exploring the use of optical crystals for the lenses as an alternative to glass. Crystal materials can have a refractive index of 2.3 and higher. This increases the field-of-view and enables channeling of all three colors through a single waveguide, instead of the two or three layers that are required when using glass. This helps reduce the weight of the AR goggles and makes the user experience more immersive.

Optical Sensors

Coherent is already a leading manufacturer in the production of components and modules for laser-based depth or 3D sensors. Specifically, our high-power VCSEL sources (both single emitters and arrays) are widely used in popular smartphones. These sources include arrays for time-of-flight (TOF) or structured light depth sensing modules. Plus, we can mate our VCSEL arrays with our diffractive or meta-surface components to produce a uniform flood illumination or dot patterns. We also design and manufacture laser driver ICs and can integrate all these components into ultra-compact modules. Our photonics experts understand that small form factor and low power consumption are the key metrics when it comes to 3D sensing for AR applications.

AR and VR headsets are positioned to become the next major consumer electronics device and internet appliances. Coherent possesses the most comprehensive portfolio of photonics-based technologies applicable to making AR goggles. This uniquely positions us to support innovation in the field – specifically delivering manufacturing tools and components that will enable the ultra-compact size, low power consumption, and high-performance devices necessary for widespread market success.