Terecircuits' founder gives us the latest updates and his views on the microLED industry, towards his upcoming talk at MicroLED-Connect

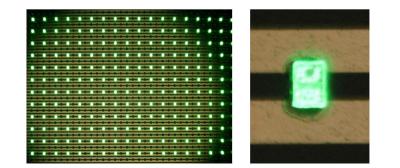

US-based Terecircuits develops technologies and manufacturing processes for microassembly based on a new class of photo-chemical polymers. The company focuses on the development of a microLED photo-chemical mass transfer process. The company's CEO, Wayne Rickard, will give a talk at the upcoming MicroLED-Connect startup showcase event later this week, and he was kind enough to send us a short update on the company's technology and status, and his views on the microLED industry and market.

Hello Wayne, thank you for your time. Can you tell us a bit about Terecircuits, your technology and current status?

Terecircuits is a Materials Company with leading-edge know-how in synthesis, characterization, and delivery of proprietary encapsulants, polymers, and thin film coatings for the semiconductor and display industries.

In general, our materials address the unique advanced packaging challenges of precision assembly: die-on-die, heterogeneous integration, 3D stacking, chiplets, SiC die attach, and – as it relates to displays - MicroLED mass transfer.