STRATACACHE CEO details the challenges and goals of the company's upcoming US-based microLED display production fab

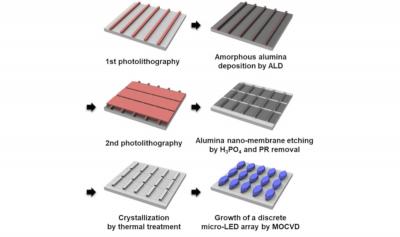

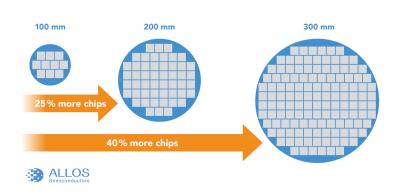

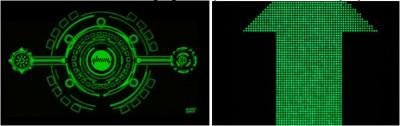

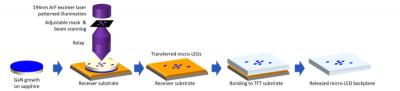

Global digital signage solution provider STRATACACHE is constructing the first US-based complete display production facility in Eugene, Oregon. The future MicroLED E4 fab is planned to commence production in 2022, and the fab will be a complete microLED production line, from epiwafer (on 300 mm silicon wafers), through transfer process and to final module assembly.

This project is extremely interesting, and we set out to discuss it with STRATACACHE's founder and CEO, Chris Riegel. At STRATACACHE, Chris leads strategic direction, technology development and engineering operations, and the MicroLED fab project seems to be personally spearheaded by him.