UK-based Optovate recently announced that it has developed a parallel aligned Micro-LED transfer process. Today the company revealed more details about its Micro-LED technology.

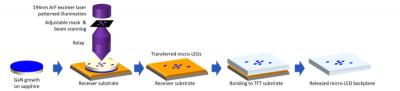

Optovate p-LLO transfer process

Optovate p-LLO transfer process

Since 2008, Optovate develops catadioptric micro-optic arrays to enhance the benefits of micro-LED, mini-LED and OLED displays. The company also developed a patterned laser lift-off (p-LLO) micro-LED transfer process.

Optovate says that for direct micro-LED and OLED displays the collection capability of the catadioptric micro-optic increases the brightness of the display by a factor of 2-3 by collecting more light and increasing the amount of light emitted at useful viewing angles. The company's process used an excimer laser to illuminate sparsely separated die sized regions of gallium nitride at the growth interface to a sapphire wafer.

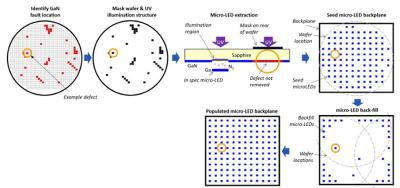

micro-LED fault and array uniformity optimization

micro-LED fault and array uniformity optimization

The UV exposure creates gallium metal and nitrogen gas which can controllably ablate the micro-LEDs onto a receiver tool or substrate. The selective optical addressing capability of p-LLO enables pre-transfer characterization data on wafers to be coded into the micro-LED extraction patterns and used for seeding and back filling micro-LED backplanes for yield optimization. The company expects its IP to enable similar performance boosts for silicon growth substrate.

Comments

Dear Robert,

Dear Robert,

Would it be possible to have access to a larger/better quality picture of Optovate process?

Regards,

Jose

In reply to Dear Robert, by José Carreira (not verified)

Jose, yes, you can click on

Jose, yes, you can click on the photos to view a larger image...

Jose, yes, you can click on

Jose, yes, you can click on the photos to view a larger image...

Dear Robert,

Dear Robert,

Would it be possible to have access to a larger/better quality picture of Optovate process?

Regards,

Jose