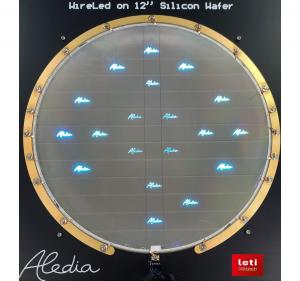

Mojo Vision lit up its first 300 mm GaN-On-Silicon blue microLED wafer

AR microLED microdisplay developer Mojo Vision announced that it has achieved a process milestone and has lit-up its first 300 mm GaN-on-Silicon blue microLED array wafer. The company says it is on track to maturing its 300 mm CMOS fab process.

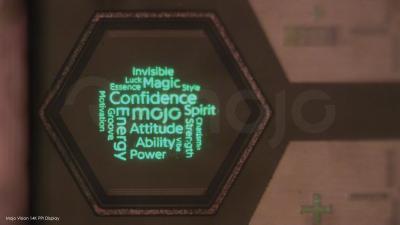

Mojo Vision is developing microdisplays based on blue LEDs and quantum dots color conversion. The company developed the world's highest density microLEDs, achieve up to 28,000 PPI (sub-micron LEDs).