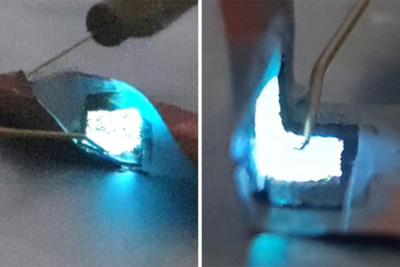

Researchers use graphene to create detachable flexible microLED devices

Researchers from the University of Texas at Dallas developed a new method to create highly flexible microLED chips, that can be folded and twisted. The LEDs are detachable, and can be attached to almost an surface.

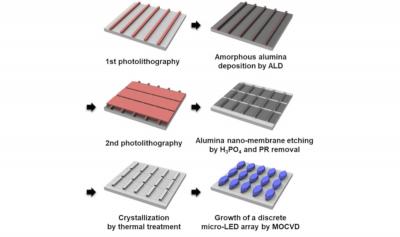

The researchers used remote epitaxy, to grow the LED crystals on a sapphire crystal substrate, coated with a one-atom layer of 2D graphene, which prevents the LED to stick to the sapphire substrate.