ETRI researchers develop a highly efficient semiconductor chip packaging technology, applicable for microLED production

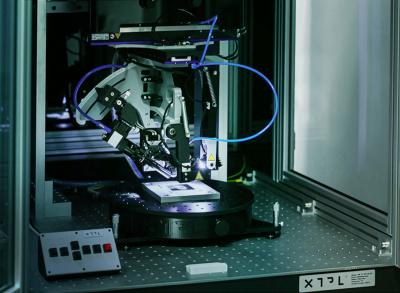

Researchers from Korea's ETRI institute developed a new chip packaging material, that is said to reduce the power consumption of the process by 95%, and reduce the number of required stages from 8 to 3. This could make semiconductors production much more efficient and lower in cost.

The technology is applicable to all high-end semiconductor production - including microLED production. Indeed the team reports that they have reached out to several microLED developers to evaluate the technology, and the initial testing has been very positive. The material could be commercialized in three years.