eLux's CEO shares his views on the microLED industry and details his upcoming talk at MicroLED-Connect

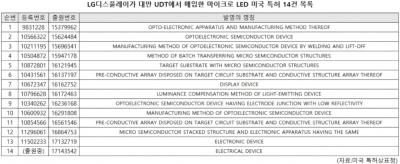

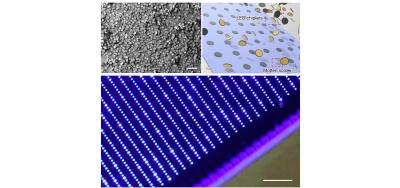

US-based eLux was established in 2016 in the USA as a spin-out from Sharp Labs of America, with an aim to develop a massively parallel assembly (transfer) process that enable low cost manufacturing of microLED displays. eLux's president and CEO Jan-Jong Lee will give a lecture at the upcoming MicroLED-Connect virtual webinar on November 2023, and was kind enough to answer a few questions we had.

Hello JJ, can you give us a short intro to your company and microLED product/service?

eLux proprietary fluidic assembly technology (FSA) has several significant advantages over conventional mass transfer methods used for competing microLED displays. Most important is that massively parallel assembly can achieve assembly rates over 5 million devices per hour using simple equipment and assembly can be scaled up to Gen 6 backplanes. eLux welcomes collaboration IP license with display companies to introduce microLED displays to the market.