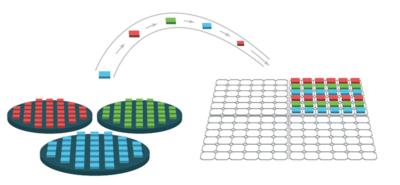

We're happy to interview eLux, as part of our new series of interviews with MicroLED Industry Association members. eLux was established in 2016 in the USA as a spin-out from Sharp Labs of America. eLux expertise and intellectual property development focus on the massively parallel assembly processes that enable low cost manufacturing of microLED displays.

Q: Hello! Can you introduce your company and technology?

eLux, Inc. was founded in 2016 as a spin-out from Sharp Laboratories of America. eLux's objective is to develop direct emission displays based on microLED technology targeting large format displays for video wall and television applications. Core personnel of eLux, including Jong-Jan Lee (President and CEO) and Paul Schuele (CTO), had extensive experience in display development working at Sharp Labs.

A 2X8 tiled microLED display made in collaboration with a large display company shown at Touch Taiwan 2022

The work done at company headquarters in Vancouver, Washington consists of development of fundamental microLED assembly technology and characterization of display performance and reliability. Direct emission display development involves extensive collaboration with microLED suppliers and manufacturers of display backplanes, so significant effort is involved in prototype fabrication, which takes place in Taiwan.