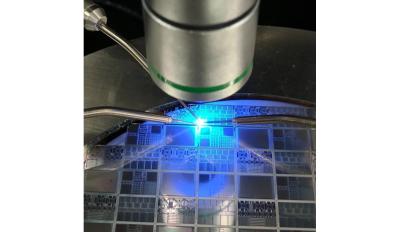

HP proposes a composable monitor design, based on microLED tiles

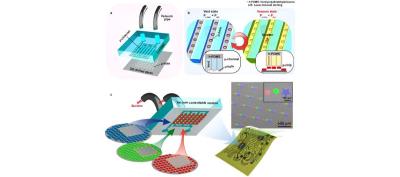

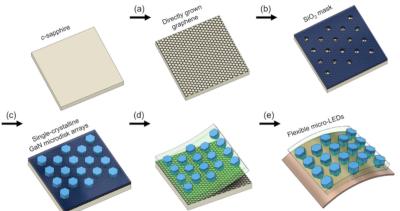

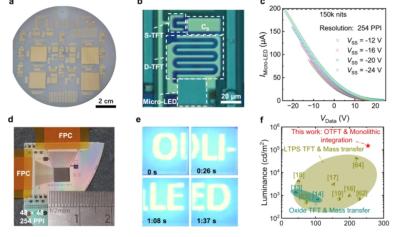

Researchers from HP propose a new composable monitor design - that is based on microLED display modules (tiles) that can connect together to construct complete monitors. The researchers explain that microLED is a key technology as it enables a bezel-less design.

The main idea is to create Lego-like building blocks, both flat and curved, that can connect in both horizontal and vertical configurations.