KAIST researchers develop a universal selective transfer process via micro-vacuum force

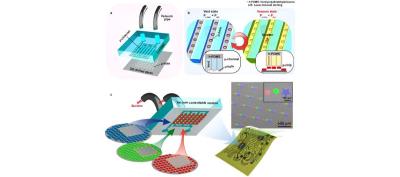

Researchers from Korea's KAIST institute developed a new microLED selective mass transfer process based on micro-vacuum force. The researchers brand their technology as micro-vacuum assisted selective transfer printing (µVAST), and say that it can be used to transfer a large number of microLEDs by adjusting the micro-vacuum suction force.

The process starts by forming small (20 micron, in the researchers demonstration device) holes on glass substrates using fast (7000 holes-per second) laser-induced etching (LIE). The LIE-drilled glass substrate is then connected to vacuum channels, which are controlled for selectively picking up, and the releasing, microLED devices.