InZiv manufactures rapid EL testing and inspection systems for microLED development and production. The company has deployed several systems at leading display makers all over the world, and has recently launched its first mass production tool. David Lewis, the company's CEO and co-founder, was recently interviewed by display industry consultant Ian Hendy.

You are CEO of InZiv in Jerusalem. Can you tell me a little bit about the company and what makes it special?

InZiv is the technology leader in rapid EL (electroluminescent) testing and inspection for microLEDs. Currently, the quality of microLED wafers is simply not where it needs to be, and the most reliable and accurate way to get both electrical and optical information from each and every die on the wafer is EL testing.

InZiv has a proprietary method for making contact with the microLED wafer, without any damage, and at very high speeds. We offer, on average, 6M dies per hour test speed in our first mass production tool, and intend to double that in the next generation. We have a roadmap beyond that for even higher throughputs. Users understand that die densities are going to increase as microLED chips get smaller and move from flip chips to vertical chips, so a valuable tool supplier needs a roadmap that can cope with the speed race, and we have such a roadmap.

In these measurements we give the manufacturer all the critical data they need to make accurate decisions on microLED manufacturing. The lack of such clear information today is a large contributor to the high price of microLED displays.

Of course, in addition to the technology, we also have a stellar team dedicated to our mission of being the leading microLED display testing and inspection company; our highly experienced team members are a big part of what makes InZiv special.

How are your tools differentiated?

InZiv offers the only tool that can perform actual contact EL at blindingly fast speeds, without damaging the pads or microLEDs.

The ability to do these measurements at such speeds with high accuracy, no damage, and while still providing all the critical information manufacturers want, renders this tool a real game-changer for the industry. When manufacturers can obtain the key optical and electrical data at high throughput, the yields improve and the costs drop accordingly.

Can you describe your product-line roadmap?

Our initial traction in the microLED market came via our testing and characterization tool, the OmniPix. We are currently up to the OmniPix 3.0, which adds considerably greater ease of use as well as automation.

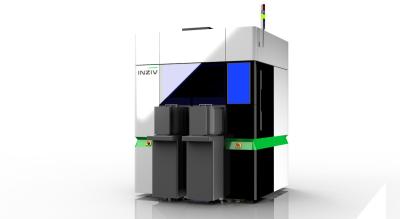

Within the past year, we have launched our mass production EL tool, the R-EL Glide.

We have a compelling roadmap of products covering many types from EL inspection to defect review, and we are also considering substrate level tools that will be critical to testing dies after mass transfer, especially vertical chips. We have defined a high growth plan across multiple segments of products, as the industry leader in our segment, and with benchmark levels of profitability - strong gross margins.

What are you enjoying about your current role and InZiv’s market position?

I love how the display technology is evolving to be seamlessly integrated into our lives, and I love being a key enabler of making these new display technologies come to life. We already have customers across the globe, and being a critical high value tool vendor means that we get to meet with everyone.

What is your view on the market at the moment?

I think everyone was a bit taken aback at the news of Apple’s apparent change of course regarding microLED back in March. That being said, it’s clear that today the microLED industry is large, strong and has its own momentum. The industry clearly remains committed to advancing this special display technology. In fact, we are beginning to see profound growth in many areas. We have come a long way as an industry, with real developments in both testing and mass transfer techniques for example over recent years.

The cost of the microLED manufacturing process now seems to be the most critical issue, and EL has a central role to play in increasing yields and lowering costs.

From many conversations with leading players across the industry, it is clear that microLED is now beginning to transition to real devices. The microLED TVs from Samsung and LG are already commercially available (while very expensive), and we expect to see more new devices this year from other players. I’m very eager to see these new product categories.

Would you say there is one geographical region that is most important for microLED? Are you able to share with us some names of your customers?

Currently, we see the Korean and Taiwanese ecosystems as the most critical hub for this developing market. China also will no doubt become an important player, and in fact the USA and Europe also have much to contribute to this technology, which makes it a bit different from LCD and OLED. microLED is truly a global business and an exciting new display technology.

Of course, I cannot say who our current customers are, for reasons of non-disclosure, but these include the important household names. Long term, we see three pools of customers: (1) large electronics companies who buy our R&D tools to help them develop microLED technology, (2) the wafer firms that build up wafer fabs, and (3) the big display companies. So we have a large and diverse pool of companies that will be our future partners and customers.

What are your biggest challenges?

We have exerted a lot of effort identifying a strong product-market fit. We are currently very focused on expanding our core team both locally and abroad, in order to successfully execute and capitalize on the exciting opportunity that we see emerging. Growing the team, while simultaneously growing our relationships with customers, and while also continuing to build out our product line, demands tremendous effort and focus. And on the day-to-day level, it is also quite challenging, but also exciting, to build a global equipment business, while many customers are also requesting demonstrations at the same time!

What do you do when you are not working? Anything else you would like to add?

My wife and I have 5 kids, so spending time with the family is something I enjoy doing and try to maximize when I am not travelling. I’ve also studied and practiced martial arts for many years; I find that it offers me a helpful outlet for physical and mental health.

InZiv will be exhibiting next week at Display Week in San Jose, and I will be presenting at the Business Conference. We invite everyone to come visit our booth #1424 to learn more. I look forward to meeting with the many wonderful members in the microLED display community. See you there!