Aledia to setup a 140 million Euros GaN-On-Si microLED production line, start making microdisplay by 2022

France-based 3D GaN LED developer Aledia announced that it plans to establish a 140 million euros LED production fab in Champagnier, near Grenoble in France. The plan is to start LED production by 2022 - and by the company will also finalize its microdisplay production process and will start offering microLED microdisplays.

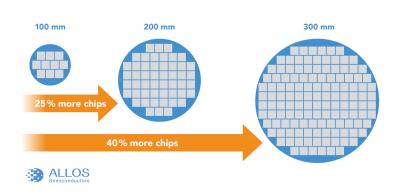

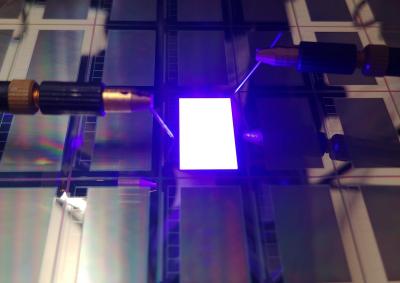

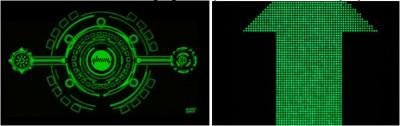

Aledia developed a microLED production process, based on a unique 3D architecture using GaN-on-silicon nanowires (branded as WireLED).