HC Semitek to use Aixtron's G5+ C MOCVD systems for microLED production

Aixtron announced that Wuhan-based HC Semitek is using Aixtron's Planetary AIX 2800G4-TM (IC2) and AIX G5+ C MOCVD systems to produce microLEDs. All of these systems, shipped in Q4 2021, feature a configuration of 8x6 inches.

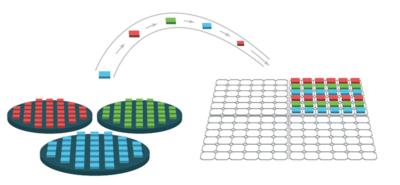

Aixtron says that this AIX G5+ C system uses wafer-level control (based on Auto-Feed Forward) of the film surface temperature during the epitaxial process in combination with Ultraviolet (UV) pyrometry. This warrants, according to Aixtron, a very accurate control of the Indium incorporation into the Multi-Quantum wells (MQW), which will ultimately define the wavelength consistency among all produced wafers