AUO and PlayNitride co-developed a 9.4" 228 PPI flexible automotive-grade microLED display

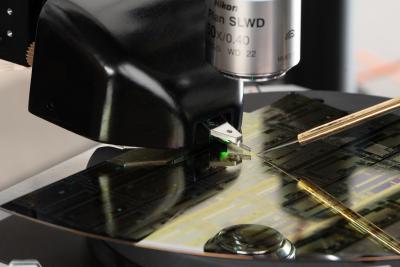

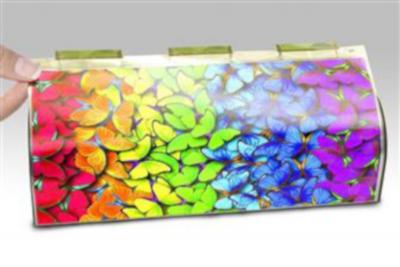

AU Optronics and PlayNitride announced that the two companies have developed a 9.4" 228 PPI flexible microLED display. The new display is driven by an LTPS backplane and the two companies say it delivers a large color gamut, is weather resistance and it is suitable for automotive applications.

AUO and PlayNitride has been collaborating on microLED display technologies for many years. In early 2019, AUO announce it plans to accelerate its development of Micro-LED products. The company previous prototype was a 12.1" 1920x720 (169 PPI) panel. In September 2019 AUO's president said that he expects Micro-LED displays to enter the market within 1-2 years, starting with large-area signage and small-sized VR displays.